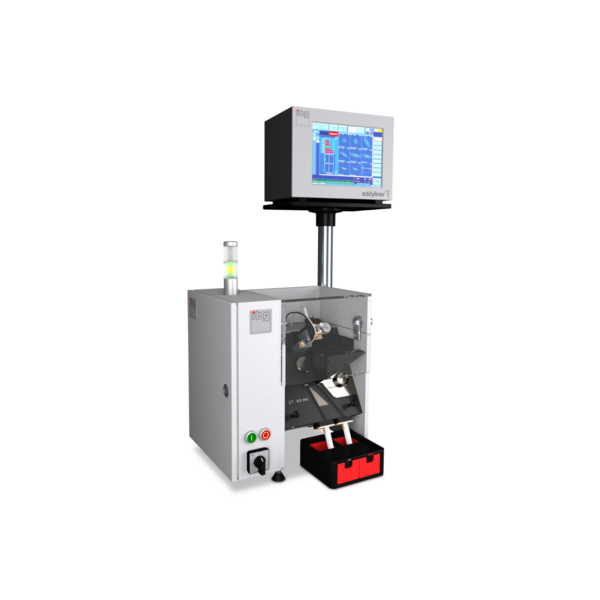

High-Speed Ball Sorting Machine: Revolutionize Production Control with ibg Ball Sorter

What would the world be without ball bearings? And what would the ball bearings be without balls? A mass product, however, with high demands on a successful heat treatment and correct use of material. Soft balls or balls out of the wrong material assembled in a safety-relevant bearing? The consequences for a manufacturer can be serious when the balls of a complete batch are faulty or a material mix-up occurrs. Even a single case costs money and gnaws at your reputation.

Ensure 100% Material Precision in Ball Bearings with ibg Ball Sorter: High-Speed Sorting Solution

Would it not be desirable to easily 100% guarantee that only balls with correct material properties are assembled into the bearings? In this case, we can support you with our well-proven ibg ball sorter. The ibg ball sorting machine guarantees that only balls with correct material properties are assembled into the bearings.

Designed for high-speed testing of complete production batches of ready-made balls it´s the perfect companion for our Aviko Ball Scanner range depending on how your production process is set up.

State-of-the-Art Technology: High-Speed, Precise, and Digital Ball Sorter Solutions by ibg

The ibg ball sorter, also known as the ball sorting machine, combines our market-leading Preventive Multi-Frequency Technology PMFT and the latest fully-digital stage of development (faster test times, enhanced frequency range, and harmonic analysis) with a very fast, precise and reliable test mechanic.

It is available as a plug-in standard product in two versions:

- for small balls (1.5 – 6.0 mm)

- for large balls (6.0 – 25.0 mm)

Special versions from 1.3 mm on or with a different size range by request.

Related to their diameter, small balls may be tested at speeds of more than 10 balls per second. The version for bigger balls may run at up to 6 balls per second.

Efficient and Precision Ball Sorting Process: Technology and Automation at Work

Balls are fed through a tube to the integrated bunker, smaller balls can also be loaded directly into the bunker. A transport disk with pockets takes the balls from the bunker and moves them below a structure probe which tests each ball.

A fast solenoid, a key component of the ball sorting machine, is installed for sorting the balls to OK or NG in order to meet the high-test speeds. Sorting is always active. The distance of the probe to the ball is diameter-dependent and set by two micrometer screws for the correct ball size related to X-and Y-values. A lockable cover prevents unauthorized access. In addition, there is a switch box with PLC, operating elements, and the power supply. The test speed (number of test parts per second) is set by varying the motor speed. A signal light on the switch box shows the actual status of the unit: Red is on in case of a standstill, and Green indicates a running machine. In case of a malfunction the red light blinks and the transport motor is stopped immediately.

Scope of supply

- ball sorter mechanic (feeder, exchangeable transport discs, discharge chute, cabling, and switch box with control electronics)

- ibg eddy current instrument eddyliner S and an ibg structure test probe

Enhancing Quality Control with ibg's Good Part Sorting Technology: Ensuring Precision in Ball Material Testing

The eddy current sorter, also known as an eddy current sorting machine, plays a crucial role in ensuring material precision in ball material testing. Testing of balls for correct material properties is always based on our eddy current structure technology PMFT. Balls that do not correspond to the correct properties are rejected. To achieve this, a certain quantity of OK balls with correct material quality is fed into the test system as reference parts. Afterward, each test part is compared with this reference data. Any discrepancy sorts the parts to NG. From a physical point of view, the permeability curves of the test parts are compared with the permeability curves of the reference parts. Important to know: ibg ball sorters are designed to test balls after fine grinding or lapping (not in a raw or rough state). At the end of your process, you test your finished product and guarantee that only OK-balls are packed and shipped to your customer. Wondering how to test larger balls with diameters >25mm? Ask our experts for tailor-made solutions with proven mechanical concepts and performance data.

Contact Us