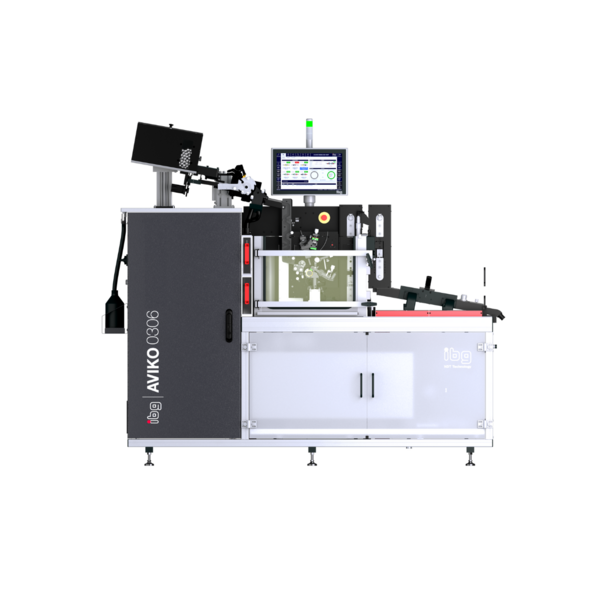

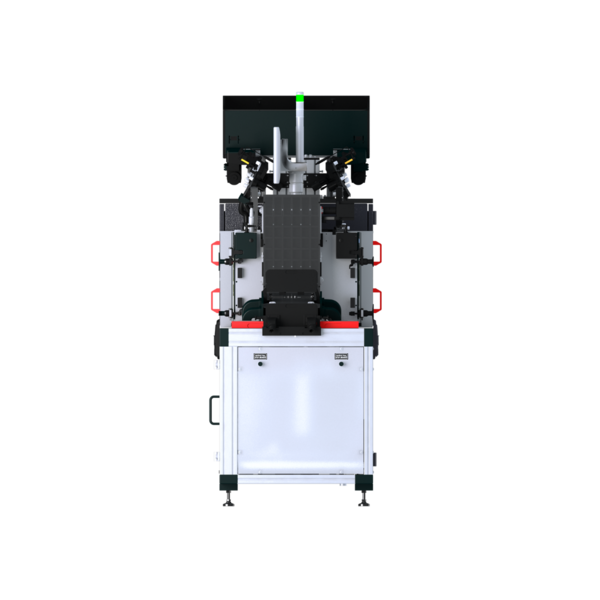

AVIKO High-Speed Ball Inspection: A Cutting-Edge Technology

Discover the cutting-edge AVIKO high-speed ball inspection technology, assessing surface and sub-surface quality at an impressive rate of up to 34,000 pcs/hr. Tailored probes match your ball material, and a variety of optional accessories, such as elevators, conservation units, demagnetizers, and packaging machines, enhance your inspection process. Achieve seamless integration, improving efficiency and precision with our complete automation solutions.

Revolutionize Ball Scanning with AVIKO G3 WET STEEL Scanner and Precision Structure Testing

AVIKO WET ball scanner performs the scan within an oil-based solution. Noise vibration reduction within the wet environment ensures a more precise and reliable inspection. One of many exciting features is that the balls do not have to be dried prior to scanning and in turn pseudo rejects due to stains or dirt are significantly reduced. This innovative technology not only saves time but also reduces the chances of false rejections, optimizing your quality control process and improving overall efficiency. Optionally, the machine can be upgraded for structure sorting, ask for more details.

Enhanced Precision: AVIKO G3 WET STEEL Diameter Validation and Structure Testing Upgrade

As part of the upgrade of our new generation AVIKO G3 machines, we have implemented a brand new diameter validation solution which is much more precise with the ability to exclude the balls that are ± 1 μm out of the selected ball diameter. Optionally diameter validation can be upgraded with a structure probe to reject the balls with different structures than calibrated. The balls are rejected prior to the monitoring point scanning which prevents additional wear and tear of the machine parts with NOK balls.

Order Information

| Model | Sorting Diameter (mm) | Order Number |

|---|---|---|

| AVIKO 0306 G3 WET - STEEL | 2.778 – 6350 | K 092 000 |

| AVIKO 0610 G3 WET - STEEL | 5.556– 10.319 | K 092 200 |

| AVIKO 1014 G3 WET - STEEL | 9.500 – 14.286 | K 092 400 |

| AVIKO 1419 G3 WET - STEEL | 13.494 – 19.050 | K 092 600 |

| AVIKO 1830 G3 WET - STEEL | 18.000– 30.163 | K 092 800 |

Scan Speed

* Scan speed is calculated for both sides working in unison. (same diameter)

| Machine | Min. | Ball | Max. | Ball | Min. | Scan Speed | Max. | Scan Speed |

|---|---|---|---|---|---|---|---|---|

| [mm] | [inch] | [mm] | [inch] | Standard [pcs/hr] | Aerospace [pcs/hr] | Standard [pcs/hr] | Aerospace [pcs/hr] | |

| AVIKO 0306 G3 WET | 2.778 | 7/64 | 6.350 | 1/4 | 20 600 | 19 200 | 15 600 | 13 800 |

| AVIKO 0610 G3 WET | 5.556 | 7/32 | 10.319 | 13/32 | 20 100 | 13 900 | 13 100 | 8 500 |

| AVIKO 1014 G3 WET | 9.525 | 3/8 | 14.600 | - | 14 200 | 12 300 | 8 400 | 6 600 |

| AVIKO 1419 G3 WET | 13.494 | 17/32 | 19.050 | 3/4 | 9 300 | 7 700 | 5 600 | 4 700 |

| AVIKO 1830 G3 WET | 18.000 | - | 30.163 | 1-3/16 | 5 600 | 4 300 | 2500 | 2 000 |

| AVIKO G3 WET STEEL 0306 / 0610 / 1014 / 1419 / 1830 | |||

|---|---|---|---|

| Dimensions (L×W×H) | 2 030 × 700 × 1 850 (mm) | ||

| Weight | 400 kg | ||

| Sorting groups | 3 (OK, EOT probe rejection; EVT/ECT probe rejection) | ||

| Input Power (230V) | 230V, 50Hz/60Hz (Type E plug) | ||

| Input Power (110V) | 110V, 50Hz/60Hz (Type B plug) |

| SCAN AREA width | MAX. DEFECT size | |

|---|---|---|

| Electric optical probe | 1.2 mm | Spot defect Ø 600 μm |

| Electric vibration probe | - | Deep flat 700 μm |

| Eddy current probes | 2 mm | Crack defect 750 × 50 × 50 (μm) |

Contact Us